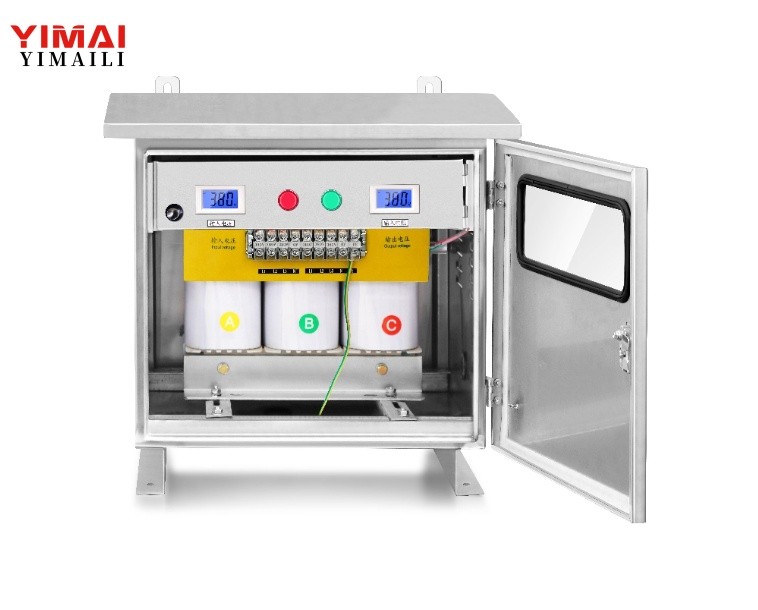

Outdoor stainless steel transformer

Outdoor stainless steel transformers are power conversion devices designed for complex outdoor environments. With stainless steel as the core protection, they integrate efficient voltage conversion and strong weather resistance, ensuring safe power transmission for outdoor distribution systems, industrial facilities, and public projects, solving issues like corrosion and short service life of ordi

- Information

1. Core Structural Composition

(1) Enclosure System

Made of 304/316L stainless steel (2-3mm thick) with wire drawing, pickling, and passivation treatment. Sealed welding and weather-resistant rubber rings achieve IP65 protection, blocking rain, dust, and UV damage, suitable for coastal, high-humidity, or dusty areas.

(2) Electromagnetic Core Components

- Iron Core: 30Q130 silicon steel sheets with multi-stage lamination (≥0.96 factor), reducing 15%-20% no-load loss vs. ordinary transformers.

- Windings: Oxygen-free copper/high-purity aluminum wires wrapped in Class H insulation (e.g., DuPont NOMEX), vacuum-impregnated for stability, segmented to enhance heat dissipation and reduce magnetic leakage.

(3) Heat Dissipation and Temperature Control System

- Heat Dissipation: Integrated fins (1.5x larger area than ordinary transformers) enable natural heat dissipation, adapting to -30℃-60℃.

- Intelligent Temperature Control: Built-in platinum sensor with digital display; alarms at 100℃, triggers overload protection at 130℃.

(4) Electrical Connection and Protection Components

- Terminal Blocks: Nickel-plated copper, sealed terminal box filled with insulating glue to prevent oxidation/short circuits.

- Insulating Accessories: Class H epoxy resin insulators (withstands 180℃), ensuring insulation and avoiding leakage.

2. Key Technical Parameters

- Capacity Range: 50kVA-1600kVA, for street lighting, charging piles, industrial plants.

- Voltage Level: Input 10kV/35kV, output customizable 0.4kV/6.3kV; voltage regulation rate ≤±2.5%.

- Loss Indicators: No-load loss (P0) as low as 0.3kW (50kVA), load loss (Pk) 1.2kW (50kVA); total loss 10%-15% below national standards.

- Short-Circuit Impedance: 4%-6%, limiting short-circuit current.

- Temperature Rise Limit: Winding ≤60K, top oil ≤55K (oil-immersed), suitable for summer high temperatures.

3. Core Performance Advantages

(1) Super Strong Weather Resistance

304 resists rain/humidity; 316L withstands salt spray/corrosive gases. Enclosure life ≥20 years (3x longer than carbon steel), cutting replacement costs.

(2) High Efficiency and Energy Saving

Low-loss core/windings save hundreds of kWh yearly. Natural heat dissipation eliminates cooling devices, reducing 40% maintenance costs vs. cooled transformers.

(3) Stability and Reliability

Class H insulation + intelligent temperature control adapts to extreme temps/load fluctuations. 25% lower fault rate vs. ordinary outdoor transformers, ensuring continuous power for charging piles, motors, and lighting.

(4) Comprehensive Safety Protection

IP65 and sealed structure prevent short circuits; nickel-plated terminals and epoxy insulators avoid leakage. Short-circuit impedance and overload protection handle line faults.

4. Typical Application Scenarios

- Municipal Outdoor Power Distribution: For street/park lighting, stable 0.4kV output, reducing maintenance.

- Outdoor Charging Pile Clusters: 50kVA-200kVA, 10kV input/0.4kV output, supporting multi-pile charging.

- Industrial Outdoor Facilities: 316L enclosure for mining/chemical equipment, ensuring production continuity.

- Ports and Terminals: Resists salt spray for shore cranes/monitoring, avoiding power-related loading delays.

5. Usage and Maintenance Points

- Installation: High, dry site with concrete foundation; avoid enclosure collision.

- Regular Inspection: Clean fins quarterly; check terminals yearly (polish if oxidized); test insulation resistance biennially.

- Special Environment Maintenance: Clean enclosure with neutral detergent every 6 months (coastal/chemical areas); check 温控 in winter.

- Fault Handling: Inspect load/heat dissipation if alarmed; shut down for oil leakage/abnormal noise, repair by professionals.

1. Core Structural Composition

(1) Enclosure System

Made of 304/316L stainless steel (2-3mm thick) with wire drawing, pickling, and passivation treatment. Sealed welding and weather-resistant rubber rings achieve IP65 protection, blocking rain, dust, and UV damage, suitable for coastal, high-humidity, or dusty areas.

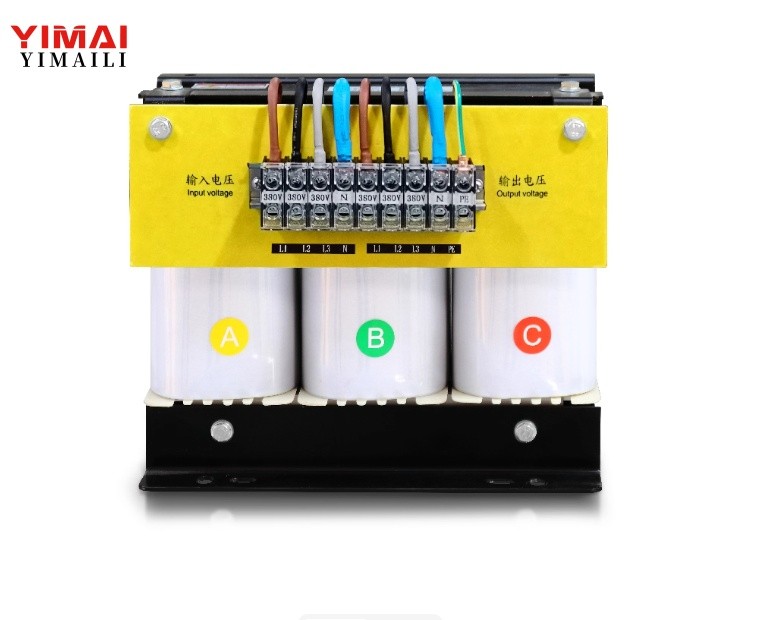

(2) Electromagnetic Core Components

- Iron Core: 30Q130 silicon steel sheets with multi-stage lamination (≥0.96 factor), reducing 15%-20% no-load loss vs. ordinary transformers.

- Windings: Oxygen-free copper/high-purity aluminum wires wrapped in Class H insulation (e.g., DuPont NOMEX), vacuum-impregnated for stability, segmented to enhance heat dissipation and reduce magnetic leakage.

(3) Heat Dissipation and Temperature Control System

- Heat Dissipation: Integrated fins (1.5x larger area than ordinary transformers) enable natural heat dissipation, adapting to -30℃-60℃.

- Intelligent Temperature Control: Built-in platinum sensor with digital display; alarms at 100℃, triggers overload protection at 130℃.

(4) Electrical Connection and Protection Components

- Terminal Blocks: Nickel-plated copper, sealed terminal box filled with insulating glue to prevent oxidation/short circuits.

- Insulating Accessories: Class H epoxy resin insulators (withstands 180℃), ensuring insulation and avoiding leakage.

2. Key Technical Parameters

- Capacity Range: 50kVA-1600kVA, for street lighting, charging piles, industrial plants.

- Voltage Level: Input 10kV/35kV, output customizable 0.4kV/6.3kV; voltage regulation rate ≤±2.5%.

- Loss Indicators: No-load loss (P0) as low as 0.3kW (50kVA), load loss (Pk) 1.2kW (50kVA); total loss 10%-15% below national standards.

- Short-Circuit Impedance: 4%-6%, limiting short-circuit current.

- Temperature Rise Limit: Winding ≤60K, top oil ≤55K (oil-immersed), suitable for summer high temperatures.

3. Core Performance Advantages

(1) Super Strong Weather Resistance

304 resists rain/humidity; 316L withstands salt spray/corrosive gases. Enclosure life ≥20 years (3x longer than carbon steel), cutting replacement costs.

(2) High Efficiency and Energy Saving

Low-loss core/windings save hundreds of kWh yearly. Natural heat dissipation eliminates cooling devices, reducing 40% maintenance costs vs. cooled transformers.

(3) Stability and Reliability

Class H insulation + intelligent temperature control adapts to extreme temps/load fluctuations. 25% lower fault rate vs. ordinary outdoor transformers, ensuring continuous power for charging piles, motors, and lighting.

(4) Comprehensive Safety Protection

IP65 and sealed structure prevent short circuits; nickel-plated terminals and epoxy insulators avoid leakage. Short-circuit impedance and overload protection handle line faults.

4. Typical Application Scenarios

- Municipal Outdoor Power Distribution: For street/park lighting, stable 0.4kV output, reducing maintenance.

- Outdoor Charging Pile Clusters: 50kVA-200kVA, 10kV input/0.4kV output, supporting multi-pile charging.

- Industrial Outdoor Facilities: 316L enclosure for mining/chemical equipment, ensuring production continuity.

- Ports and Terminals: Resists salt spray for shore cranes/monitoring, avoiding power-related loading delays.

5. Usage and Maintenance Points

- Installation: High, dry site with concrete foundation; avoid enclosure collision.

- Regular Inspection: Clean fins quarterly; check terminals yearly (polish if oxidized); test insulation resistance biennially.

- Special Environment Maintenance: Clean enclosure with neutral detergent every 6 months (coastal/chemical areas); check 温控 in winter.

- Fault Handling: Inspect load/heat dissipation if alarmed; shut down for oil leakage/abnormal noise, repair by professionals.

Get the latest price? We'll respond as soon as possible(within 12 hours)