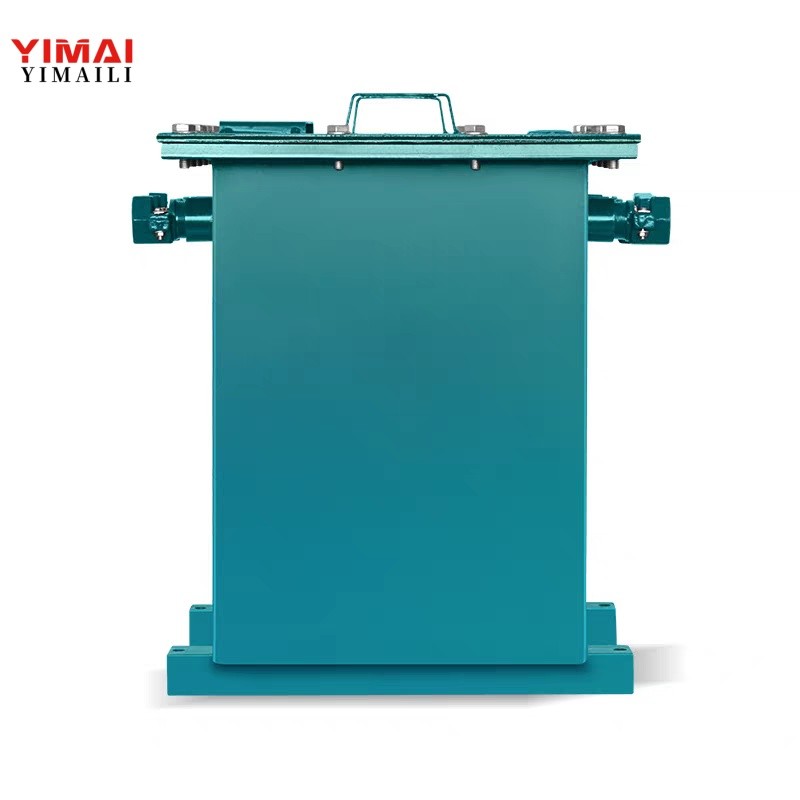

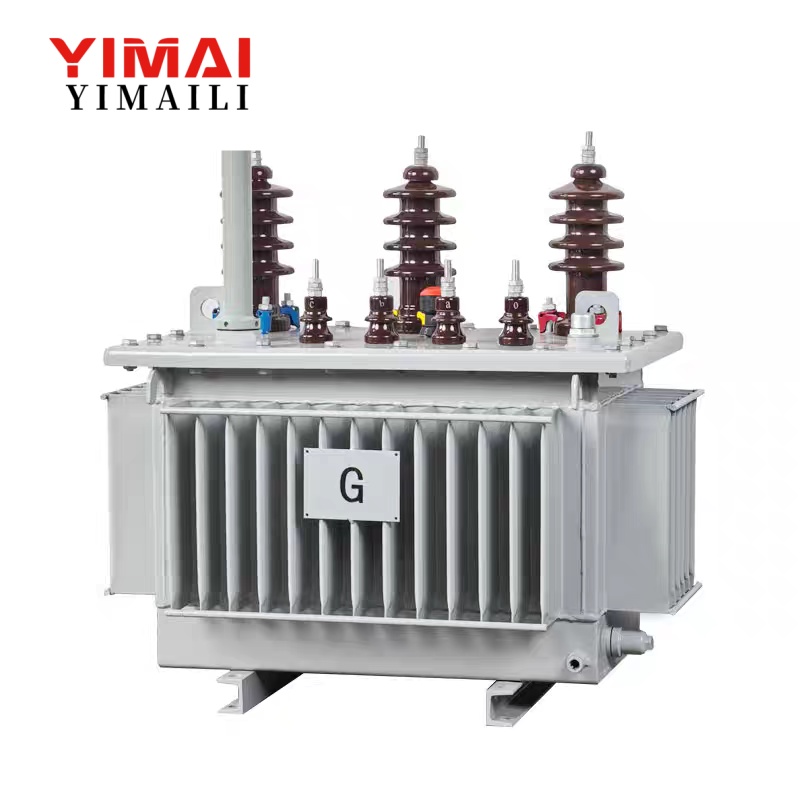

Mine transformer

The mine-used flameproof dry-type transformer is a special power equipment designed for explosive gas environments such as coal mines. It belongs to a special type of dry-type transformer. Using the principle of electromagnetic induction, through the primary and secondary windings on the closed iron core, AC power of one voltage level is converted into AC power of another voltage level with the sa

- Information

1.Structural Features

- Flameproof Shell: This is a key feature of the transformer. The shell is made of high-strength steel plates and undergoes special processing techniques such as welding and grinding to ensure sufficient mechanical strength. It can withstand the pressure generated by internal explosions without damage and prevent internal flames from spreading to the outside, thereby avoiding explosions in the external explosive gas environment.

- Dry-type Windings: Windings cast with epoxy resin are used, and insulating oil is not required. Epoxy resin has good electrical insulation performance, mechanical performance, and heat dissipation performance, which can effectively prevent faults such as winding moisture and short circuit. Compared with oil-immersed transformers, it eliminates the hidden dangers of oil leakage and fire, and has higher safety.

- Terminal Box: It is equipped with a special flameproof terminal box for connecting power input and load output. The electrical connection points inside the terminal box are specially treated to ensure good electrical contact, and at the same time, it has flameproof performance to prevent electric sparks generated at the wiring from causing danger.

- Heat Dissipation Structure: Heat dissipation is achieved through heat dissipation fins on the shell or by using air-cooling devices. The heat dissipation fins increase the heat dissipation area of the shell and improve the natural heat dissipation efficiency; the air-cooling device starts when the transformer load is large and the temperature is high, accelerating air flow, enhancing the heat dissipation effect, and ensuring that the transformer operates within the specified temperature range.

2. Performance Advantages

- High Safety: The flameproof design and dry structure enable it to operate safely in flammable and explosive environments such as underground coal mines, effectively preventing explosion accidents caused by electrical equipment, and ensuring mine safety production and personnel life safety.

- Moisture-proof and Dust-proof: The dry-type winding is sealed by epoxy resin, which can effectively resist the harsh environment of humidity and dust in the mine, reduce the occurrence of electrical faults, and improve the reliability and service life of the equipment.

- Easy Maintenance: Compared with oil-immersed transformers, there is no need to regularly check and replace insulating oil, reducing maintenance workload and maintenance costs. At the same time, the dry structure makes the internal structure of the transformer clearer, facilitating maintenance and fault 排查.

- Small Size and Light Weight: Since there is no insulating oil and complex oil circulation system, the overall volume and weight are relatively small, which is convenient for transportation and installation in narrow spaces in mines.

3. Technical Parameters

- Rated Capacity: Common specifications include 200kVA, 500kVA, 1000kVA, etc., which can be selected according to the power requirements of electrical equipment in different areas of the mine.

- Rated Voltage: The primary side voltage is commonly 6kV, 10kV, etc., and the secondary side voltage is 400V, 690V, etc. according to load requirements to meet the power supply requirements of different equipment underground in coal mines.

- Short-circuit Impedance: Generally between 4% - 6%, which affects the short-circuit current and voltage regulation rate of the transformer. Appropriate short-circuit impedance can ensure the stability and power supply quality of the transformer in case of faults.

- Insulation Grade: Usually grade F or H, with high heat resistance, and can operate stably for a long time in a relatively high temperature environment.

4. Application Scenarios

- Coal Mining: It provides stable power supply for underground power equipment such as shearers, roadheaders, and scraper conveyors to ensure the normal operation of coal mining operations.

- Mine Ventilation: It supplies power to equipment such as ventilators to ensure air circulation in the mine, discharge harmful gases, and maintain a good working environment underground.

- Mine Drainage: It supplies power to drainage pumps to discharge accumulated water in the mine in a timely manner, prevent flooding accidents, and ensure mine safety production.

5. Precautions for Use and Maintenance

- Installation Environment: It should be installed in a place with good ventilation, no dripping water, no severe vibration and impact, and there should be no corrosive gas and conductive dust around.

- Operation Monitoring: Regularly monitor the operating temperature, voltage, current and other parameters of the transformer to ensure that it operates within the rated range. When the temperature is too high or the current is abnormal, the cause should be found out in time and corresponding measures should be taken.

- Maintenance Inspection: Regularly check the integrity of the flameproof shell to see if there are cracks, deformations, etc.; check whether the wiring in the terminal box is loose and whether there are signs of overheating; clean the dust on the surface of the transformer and the heat dissipation fins to ensure the heat dissipation effect.

- Fault Handling: When the transformer fails, it should be overhauled by professional electrical maintenance personnel. It is strictly forbidden to carry out maintenance operations without power failure or without taking safety measures to avoid electric shock or explosion accidents.

1.Structural Features

- Flameproof Shell: This is a key feature of the transformer. The shell is made of high-strength steel plates and undergoes special processing techniques such as welding and grinding to ensure sufficient mechanical strength. It can withstand the pressure generated by internal explosions without damage and prevent internal flames from spreading to the outside, thereby avoiding explosions in the external explosive gas environment.

- Dry-type Windings: Windings cast with epoxy resin are used, and insulating oil is not required. Epoxy resin has good electrical insulation performance, mechanical performance, and heat dissipation performance, which can effectively prevent faults such as winding moisture and short circuit. Compared with oil-immersed transformers, it eliminates the hidden dangers of oil leakage and fire, and has higher safety.

- Terminal Box: It is equipped with a special flameproof terminal box for connecting power input and load output. The electrical connection points inside the terminal box are specially treated to ensure good electrical contact, and at the same time, it has flameproof performance to prevent electric sparks generated at the wiring from causing danger.

- Heat Dissipation Structure: Heat dissipation is achieved through heat dissipation fins on the shell or by using air-cooling devices. The heat dissipation fins increase the heat dissipation area of the shell and improve the natural heat dissipation efficiency; the air-cooling device starts when the transformer load is large and the temperature is high, accelerating air flow, enhancing the heat dissipation effect, and ensuring that the transformer operates within the specified temperature range.

2. Performance Advantages

- High Safety: The flameproof design and dry structure enable it to operate safely in flammable and explosive environments such as underground coal mines, effectively preventing explosion accidents caused by electrical equipment, and ensuring mine safety production and personnel life safety.

- Moisture-proof and Dust-proof: The dry-type winding is sealed by epoxy resin, which can effectively resist the harsh environment of humidity and dust in the mine, reduce the occurrence of electrical faults, and improve the reliability and service life of the equipment.

- Easy Maintenance: Compared with oil-immersed transformers, there is no need to regularly check and replace insulating oil, reducing maintenance workload and maintenance costs. At the same time, the dry structure makes the internal structure of the transformer clearer, facilitating maintenance and fault 排查.

- Small Size and Light Weight: Since there is no insulating oil and complex oil circulation system, the overall volume and weight are relatively small, which is convenient for transportation and installation in narrow spaces in mines.

3. Technical Parameters

- Rated Capacity: Common specifications include 200kVA, 500kVA, 1000kVA, etc., which can be selected according to the power requirements of electrical equipment in different areas of the mine.

- Rated Voltage: The primary side voltage is commonly 6kV, 10kV, etc., and the secondary side voltage is 400V, 690V, etc. according to load requirements to meet the power supply requirements of different equipment underground in coal mines.

- Short-circuit Impedance: Generally between 4% - 6%, which affects the short-circuit current and voltage regulation rate of the transformer. Appropriate short-circuit impedance can ensure the stability and power supply quality of the transformer in case of faults.

- Insulation Grade: Usually grade F or H, with high heat resistance, and can operate stably for a long time in a relatively high temperature environment.

4. Application Scenarios

- Coal Mining: It provides stable power supply for underground power equipment such as shearers, roadheaders, and scraper conveyors to ensure the normal operation of coal mining operations.

- Mine Ventilation: It supplies power to equipment such as ventilators to ensure air circulation in the mine, discharge harmful gases, and maintain a good working environment underground.

- Mine Drainage: It supplies power to drainage pumps to discharge accumulated water in the mine in a timely manner, prevent flooding accidents, and ensure mine safety production.

5. Precautions for Use and Maintenance

- Installation Environment: It should be installed in a place with good ventilation, no dripping water, no severe vibration and impact, and there should be no corrosive gas and conductive dust around.

- Operation Monitoring: Regularly monitor the operating temperature, voltage, current and other parameters of the transformer to ensure that it operates within the rated range. When the temperature is too high or the current is abnormal, the cause should be found out in time and corresponding measures should be taken.

- Maintenance Inspection: Regularly check the integrity of the flameproof shell to see if there are cracks, deformations, etc.; check whether the wiring in the terminal box is loose and whether there are signs of overheating; clean the dust on the surface of the transformer and the heat dissipation fins to ensure the heat dissipation effect.

- Fault Handling: When the transformer fails, it should be overhauled by professional electrical maintenance personnel. It is strictly forbidden to carry out maintenance operations without power failure or without taking safety measures to avoid electric shock or explosion accidents.

Product Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)